Get a first look at this ZED consulting project (energy + HVAC design) in Harwich Port, MA where a hempcrete house is being built, one of the first of its kind in the country. ZeroEnergy Design provided the energy consulting and mechanical design for this forward-looking, carbon sequestering home.

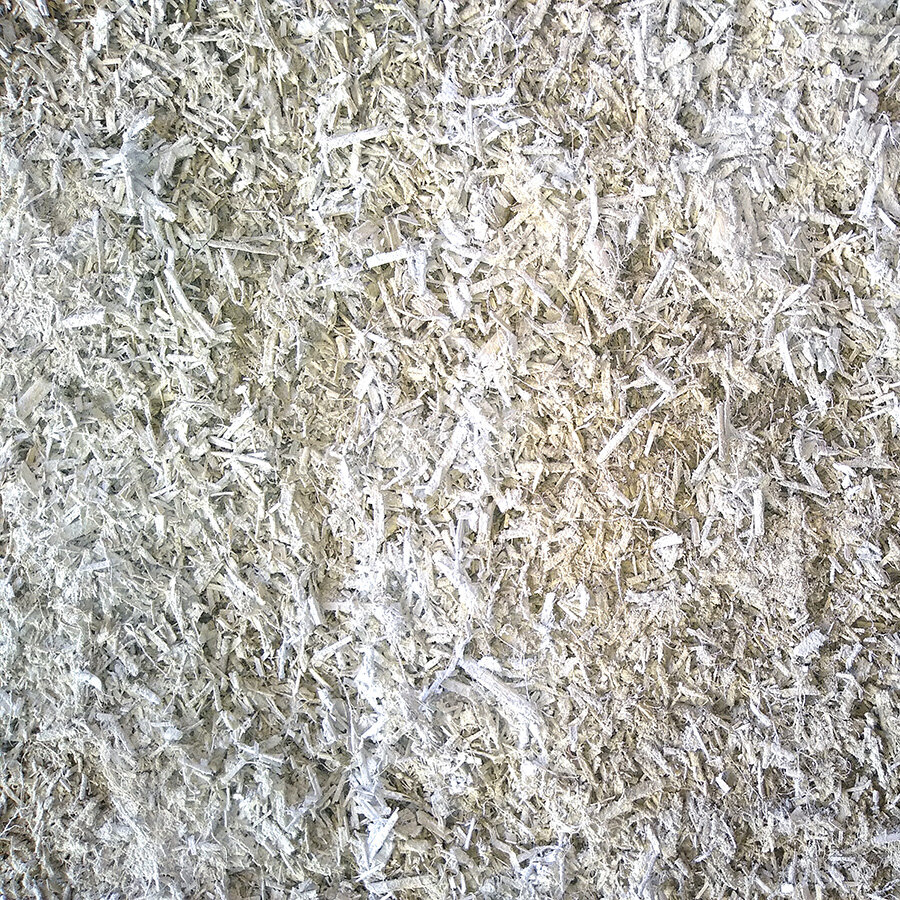

What is Hempcrete?

Hempcrete is a cutting edge biocomposite building material made from the chopped stalk of the hemp plant, a lime-based binder, and water. The result is a healthy, resilient and carbon beneficial building material that can be used to create a building’s thermal envelope, and which looks a bit like concrete. But unlike concrete, hempcrete actually sequesters carbon dioxide; a recent study showed that hempcrete can sequester 19 pounds of C02 per cubic foot. This progressive material is incredibly useful for: 1) reducing a building’s operational energy requirements with a well insulated, thermally broken, airtight enclosure, 2) sequestering carbon in the material itself, and 3) providing healthy indoor air via thermal mass and moisture absorbing behavior.

Material Attributes

Lime in the application of hempcrete uses about 80% less energy to calcine than when used in concrete. As an ‘air set’ material, the lime in hempcrete reabsorbs the CO2 that is driven off in calcining.

Hempcrete is resistant to mold growth, deters pests and won’t burn. The vapor permeable property of hempcrete also helps regulate building humidity, while its matrix structure provides excellent sound absorption.

In addition to being a non-toxic and biodegradable material, hempcrete can be used to reduce construction waste by replacing drywall, which represents about 10% of building construction debris. Furthermore, hemp is a rapidly renewable resource with the greatest CO2-storing potential of any other insulation building material.

The Cape Cod Hemp House

The Cape Cod Hemp House exemplifies future focused, healthy, low carbon, net positive energy design. As this progressive home takes shape, we take a closer look at the carbon sequestering envelope, all-electric systems, and renewable energy sources that contribute to its net-zero energy makeup.

Envelope

The home's super-insulated envelope begins with 12 inch-thick walls with continuous hempcrete on the exterior and spray applied to a wood frame with bamboo wall lathe. The interior will be finished with a plaster coat. The roof includes hempcrete, wood sheathing, building wrap, and metal roofing. Triple pane windows round out the super insulated, airtight building enclosure.

Systems

High efficiency systems in the home include air source heat pumps, a heat pump hot water heater, and energy recovery ventilation. Rightsized air source heat pumps provide heating and cooling matched with the thermally improved building enclosure. Balanced heat and energy mechanical ventilation systems provide constant fresh air while also managing humidity levels. A heat pump hot water heater efficiently provides domestic hot water.

Renewables

The all-electric home’s consumption is offset with clean energy production on the roof from a 15kW solar electric system with a whole-house backup battery. The photovoltaic array is expected to offset 120% of the total annual energy consumption, resulting in a net positive energy house.

A Future for Hempcrete

While builders continue to see value in hempcrete, one of the limitations to its wider use is availability. Facilities capable of processing hemp into hempcrete are mostly in Europe and some regulatory challenges still exist in growing hemp itself, particularly in the U.S. But once more forward-thinking producers and builders start utilizing hemp for construction, it could lead to many more eco-friendly, high performance buildings.

MORE: CAPE COD HEMP HOUSE